Mandatory Quality Assurance Procedure. Quality is only the beginning of our service.

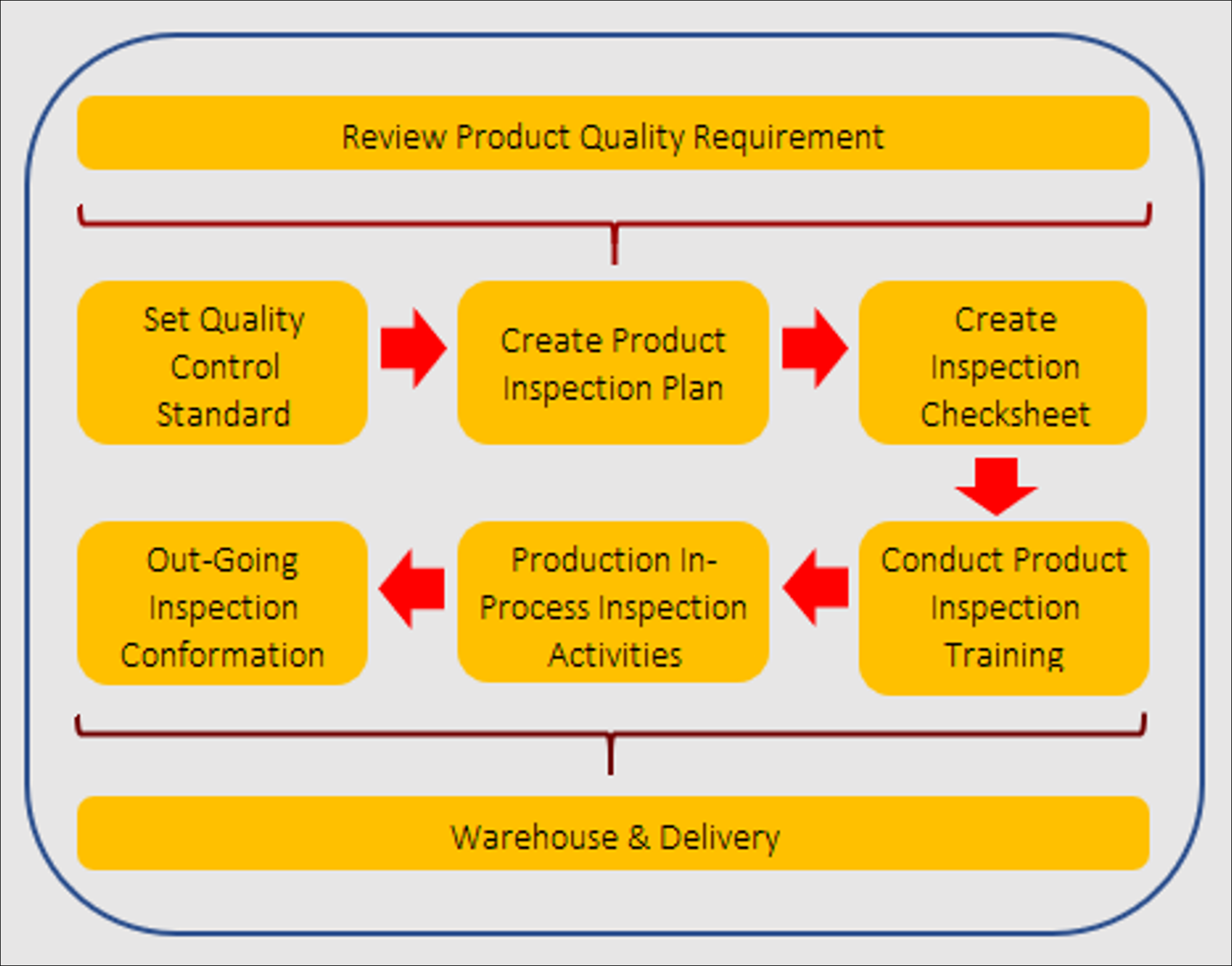

The quality control begin from testing products, reviewing manufacturing processes, and creating benchmarks, detection capability and inspection plan. The purpose of the quality control is to determine any needs for corrective actions in the manufacturing process. This is all done to monitor significant variations in a product in fulfilling quality requirements. The customers expect and demand for high-quality products.

By monitoring products quality in the process as well as reviewing the products’ design, the early detection able to minimized defective products been delivered to customer.

Adopting the effective quality control in manufacturing is more involved in two levels : –

Being aware of common defects in a plastic injection molding. Knowing and understanding the defects also helps pinpoint the underlying cause of the problem.

The injection plastics molding defects could be attributed mainly from the following causes : –